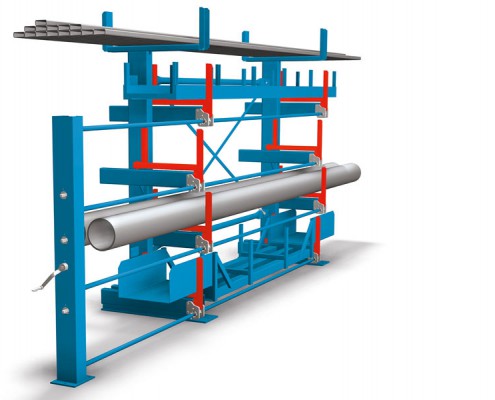

Roll Out Cantilever Racking

Rack systems combine storage density with selectivity for stock, tubing, or pipe storage applications

Advantages of the roll-out racks:

-

Space gain

Storage is done directly with the hall crane. Wider aisles for forklift trucks, stacking cranes, etc. are therefore unnecessary -

Excess lengths

Storage of lengthy goods with a length of 25 m and above possible -

Safety

Entire roll-out rack can be accessed and loaded or unloaded freely, no “pushing in” or “pulling out” of the shelves necessary -

Time-saving

Without restacking using the hall crane, the racks can be loaded, or transport vehicles can be loaded or unloaded -

Quick

As it can be accessed quickly at any time -

Easy handling

The rack can usually be operated by one person -

Space-saving

Wide aisles for lift trucks or forklifts are also unnecessary on the side ends, as lengthy goods can easily be handled by means of the warehouse crane.Working method:

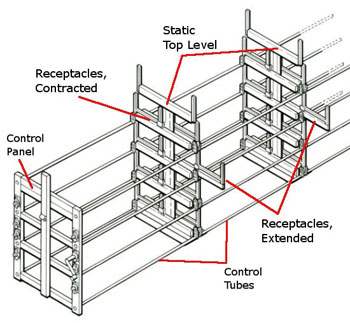

A crank turning a spindle rolls out each arm of the roll-out rack. The roll-out movement is controlled and limited by the depth of the shelf arm. The ratio of spindle shaft to crank rotation is 2.36: 1. With a full load of 5,000 kg, an initial crank force of approx. 15 kg may be required. After that, only little force is necessary. Each rack unit consists of at least two base structures, longitudinal binders and a control mast for for each rack side. Depending on the type of lengthy goods, several base structures can be implemented for each rack at a customer-specified spacing. Storing the goods on very high shelves is possible with the help of e. g. platform ladders or lifts. Residual lengths can be stacked with supporting pallets, or the shelf arm spacing is set as required.

Design:

-

Special rotary and rigid construction.

-

Moving parts are supported by ball bearings.

-

The individual structures (two control masts and two rack structures in the standard version) are completely welded and assembled units.

-

The cross-toothed driveshaft has a non-slip surface providing a good grip in order to ensure controlled rotary and roll-off movements of the pushing arm even under load.

-

Standard colours: Structure blue RAL 5012, roll-out arms red RAL 2002.

-

Per request: Custom dimensions and paint coats available in all RAL colours – please inquire!

Customer-specific roll-out racks

If you need to store special materials or certain spatial requirements must be met, our consulting engineers will be happy to create individual concepts for you.

Optional accessory for roll-out racks

-

Trays and boxes for leftover pieces

-

Electrically driven roll-out shelves

-

Various colours / custom paint coats in all RAL colours

-

Custom dimensions

Safety thanks to rack inspection

Cassette racks require mandatory inspection. As safety is always a top priority, we offer rack inspections according to DIN EN 15635. Serious accidents and high repair costs can be avoided by effectively preventing damage to the storage equipment! Our TÜV (German Technical Inspectorate) certified rack checker provides the annual safety check for your warehouse equipment in accordance with DIN EN 15635 according to BGR 234.

Cantilever racks allow you to get stock (like steel, Aluminium, or iron) into racks off the floor.

Cantilever racks allow you to get stock (like steel, Aluminium, or iron) into racks off the floor.

- Quick Access in Narrow aisles

- Quick access in narrow aisles

- Safe because of flexible loading by means of a crane system

- High load capacity

- Excess lengths are no problem

- Time saving for stacking and unstacking

- Gain more space in narrow warehouse

Roll Out Cantilever Racking

Roll Out Cantilever Racking

- Designed

- Specially torsion free and rigid construction.

- All moving parts are mounted on roller bearings.

- The individual structures (2 control masts and 2 rack structures) are completely welded and assembled units.

- Being cross-toothed, the driveshaft has a non-slip surface providing a good grip in order to ensure controlled rotary and roll off movements of the pushing arm even under load.

- Rack and shelf height are variable

Principle

- A crank turning a spindle rolls out each rack arm.

- Rolling out is carried out in a controlled manner and is limited by the depth of the arm. The ratio of spindle shaft to crank rotation is 2.36 : 1. With a full load 5 000 kg, an initial crank force of approx. 15 kg may be required; once in motion, only little force is needed.

- Each rack unit consists of at least 2 base structures, longitudinal binders and control mast for each rack side.

- Depending on the type of lengthy goods, several base structures can be implemented for each rack at a customer-specific spacing.

- Residual lengths can be stacked with supporting pallet or shelf arm spacing is set as required.